By Monica Schultes

This article was originally published in PCI Ascent Winter 2023 issue.

PCI Ascent’s Monica Schultes recently spoke with Emily Lorenz, PE, expert in sustainable building construction practices and primary author of a new PCI white paper “Suitability of Environmental Product Declarations (EPD) in Material Selection.” Responses have been edited for clarity and brevity.

Monica Schultes: Why write this white paper on EPDs?

Emily Lorenz: While EPDs have been around for a while—the ISO standard was published in 2006—there is an urgent need to get this information into the hands of owners and designers. Efforts like “Buy Clean” [a U.S. government policy to promote construction materials and products with lower embodied greenhouse gas emissions] are admirable and encourage the AEC [architecture, engineering, and construction] community to responsibly select resilient materials. However, they sometimes allow EPDs to be misused.

For example, some proposed legislation and procurement language do not follow the standards and permit comparisons across PCRs [product category rules] or ignore impacts over the full life cycle of a product, which may be a detriment to the entire structure. This frequent misinterpretation demonstrates that guidance and information are needed in the marketplace.

Some refer to EPDs like nutrition labels for environmental attributes. Is that an apt description?

It is a good analogy, but it’s important to recognize significant distinctions. Just as a “serving size” varies for different food items, the same is true for EPDs. Environmental impacts are often measured and reported in different units, such as mass or volume. Also, an EPD does not say whether a given product is “good” or “bad” for the environment, just as a nutrition label doesn’t make judgments as to whether food is healthy or not. For example, when evaluating a food label, you may be more concerned with sugar if you are diabetic, or saturated fat if you have high cholesterol.

Will people look for shortcuts and try to compare apples to oranges?

It’s already happening in the marketplace, even though it is strictly forbidden by ISO standards. Usually this is done by well-meaning individuals, who do not understand all the background information needed and used when developing an EPD. An EPD looks simple, but it is based on many decisions related to data choices, all of which influence the outcome.

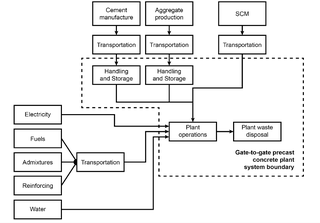

Do EPDs provide information about products from cradle to grave?

EPDs are more likely to provide information on a cradle-to-gate basis because that information is more commonly known by manufacturers. We can’t yet easily and economically create EPDs for each product and for each application for the full life cycle. If an EPD is created on a cradle-to-grave basis, it is usually based on what we call a scenario. This is a hypothetical construction, use, and end-of-life case that includes many assumptions.

An EPD looks simple, but it is based on many decisions related to data choices.

Should we focus on the cradle-to-gate, since no scenarios are needed? If we only consider cradle-to-gate, then do products with long service lives look less favorable?

We should look at a whole life, whole building life cycle assessment (LCA). That is the only way to determine the full impact of our decisions at all life cycle stages that takes into account all material and system interactions. Design decisions should never be made on a cradle-to-gate scope without considering the whole life of the structure. Once the structure has been optimized, systems chosen, and material quantities have been finalized, only then should a designer look for the “best” within a material category that meets the performance requirements.

Cradle-to-Gate System Boundary for Precast Concrete Operations

By emphasizing embodied carbon, is the industry in danger of focusing on one environmental aspect to the detriment of others?

That may be the case in the near term. There’s an urgency in the design community about reducing greenhouse gases emitted between now and 2030. However, we need to be careful about burden shifting. Choosing a lower embodied carbon material now that increases operating emissions in the long run is not the best solution. Other environmental impacts influence human health in the near term, such as smog creation and degradation of the ozone layer.

LCA is increasingly being used as a tool by the building industry to assess the global warming potential [GWP] of building activities. To avoid this burden shifting, analyses should consider multiple environmental impacts, but that is not standard practice.

While some building materials may look favorable in the short term, precast concrete is often built to last longer than others. How do you include that in an EPD?

Materials with lesser environmental impacts on a cradle-to-gate basis, but with much shorter service lives, can appear favorable by disregarding the impact of maintenance and replacement. That is why any comparison needs to take place in the context of the full life of the building. Right now it is difficult to capture that information, since it is not easy to create an EPD for products for every project and every usage. The best we can do is perform a full LCA of a building.

Will EPDs have an impact on building codes like the International Green Construction Code?

Definitely. Green building codes and standards are evolving as specifiers become more sophisticated in their knowledge of EPDs and as tools become available to allow for generation of more product- and plant-specific EPDs. We are still very much in the product-transparency and knowledge-gathering phase of using EPDs effectively.

Codes and standards go through a deliberate public review process. How is some of this new legislation different?

There could be legal and financial implications with some of these seemingly arbitrary benchmarks that have a narrow focus on GWP. In several states, cradle-to-gate-based requirements or upper limits on GWP are being incorporated into building regulations. Much of the new “Buy Clean” legislation has skipped the transparency and local-EPD-gathering phase and has jumped straight to setting benchmarks for certain materials based on national industry-average EPD values. This creates a patchwork of requirements across the country, and isn’t the best way to reduce environmental impact locally. The fuels used in the local utility grid greatly influence a product, system, or building environmental impact. National industry-average benchmark values may be easy for manufacturers to meet in a region that has a “cleaner” local grid, and impossible to meet in a location that has a “dirty” grid. It is better to survey what is possible in a locality and make improvements from there. Procedures to create meaningful benchmarks for products and carbon budgets for building are being developed in green building codes and standards committees, but this thoughtful process takes time.

Are tools becoming available to make EPDs easier to use?

Architects can compare the environmental performance of different building designs with various tools that incorporate EPDs or LCAs. The LCA process is complex, but these are the best tools available at this time. Those on the leading edge are utilizing a plug-in to BIM [building information modeling] that allows real-time updates to environmental impacts during the design stage to evaluate options. Eventually, the hope is that we will be able to develop LCAs for each structure or EPDs for each application of a product in a structure.

What is the rush to establish benchmarks?

Things are moving quickly to prepare for the federally funded infrastructure work in the pipeline. Agencies are looking to EPDs and setting limits in an effort to build toward a more-resilient and zero-carbon future. But some of the guidance or model code language doesn’t conform to the requirements in the ISO standards related to comparisons. Some agencies have established environmental benchmarks that don’t correlate to current construction methods. Others are based on best practices for buildings including energy performance and construction types. This scattered approach has led to a large number of benchmarking limits with varying impacts to be considered, which makes it difficult for designers and product manufacturers to comply.

The white paper entitled “Suitability of Environmental Product Declarations (EPD) in Material Selection” is available here.

PCI committee members and staff involved in producing this white paper are: Jared Brewe, PE, PCI; Harry Gleich, PE, Metromont Corporation; Corey Greika, PE, Coreslab Structures (Indianapolis); Becky King, PCI; John Lawler, PE, Wiss Janney Elstner; Ruth Lehmann, PE, PCI West; Jane Martin, GATE Precast; and Larbi Sennour, PE, CEG International.

Emily Lorenz, PE, is an independent consultant in the areas of LCA, EPDs, PCRs, green building, and sustainability. Lorenz specializes in building code and standards work and advocacy. She participates as a voting member on several committees including the 2024 International Energy Conservation Code Commercial Committee, the ASTM International Committee E60 on Sustainability, and the American Concrete Institute’s building code subcommittee on sustainability. She also serves as an expert to the ISO Working Group on Environmental Declarations of Products, and as a voting member of the Envelope Subcommittee of ASHRAE 90.1.