St. Croix Falls High School - St. Croix Falls, WI

Whether owner, architect, engineer or contractor, each member of a project team has a vision for a perfectly executed final building. Often, that vision depends on the individual roles that they play and their past experiences, both good and bad, on other projects.

In the K12 space, preferences for masonry over prefabricated concrete systems, are often based upon familiarity and what has been used in the past. School structures in one region might typically be designed with masonry by default, whereas other regions may predominantly choose precast.

Regardless of preferences, though, prefabricated concrete systems offer certain advantages for K12 buildings that can appeal to every member of the design team.

Prefab Benefits for the Owner

Expedited Construction

Schools typically have abbreviated construction schedules, and for occupant safety, much of the site work is performed when school is not in session. As such, the speed to market afforded by prefabricated systems makes it an attractive option to owners. The panels can be produced during the school semester, and then erected in a matter of days instead of months, either once school adjourns or during an extended holiday break. That means shorter construction schedules, less general conditions paid to the contractor and fewer weather delays. And should the desired aesthetic be bricks or a block appearance, it can be incorporated into the panel designs.

Energy Efficiency

Budget constraints are a part of every district’s reality, so utilizing building solutions with life-cycle benefits is a win-win. Prefabricated wall panels include insulation, offering better thermal performance than traditional masonry block, so energy costs are lower, while also requiring fewer and/or smaller heating and cooling units. Additionally, the lack of an air cavity in the wall system virtually eliminates any risk from mold.

Prefab Benefits for the Architect

Architectural Expression

Precast systems have undergone significant enhancements and are no longer a standard gray. In recent years, they have become incredibly flexible in their design capabilities. There is an unlimited variation of colors, shapes, formliners, and masonry types from which to choose, enabling architects to create aesthetically pleasing and functional educational spaces.

Design Collaboration

Much of the early design work occurs in BIM, as both the architect and the prefabricator’s preconstruction and engineering teams work collaboratively to tweak and improve the model to achieve the design intent, looking for ways to value-optimize the overall design.

Quality Control

Given that the precast building systems are manufactured within an environmentally controlled PCI-certified environment, the quality of the product is often far superior to other systems. That can be particularly advantageous in educational buildings, as long-standing community investments for future generations.

Prefab Benefits for the Engineer

Durability & Resiliency

Precast and masonry are both inherently resilient against fire, wind, hail and snow. Precast panels are produced in factory-controlled environments with concrete compressive strengths over 5,000 psi and low water-cement ratios which ensures a dense, exceptionally durable finish.[1] This makes them also highly durable and resistant to weathering –all factors that make them a suitable building solution for educational buildings that must withstand heavy use, and abuse, over the years. Schools are often dual-purposed as community resources, and concrete building systems are well-suited for the design and construction of storm shelters, meeting ICC-500 requirements and providing a safe haven for students and the community at large.

This map shows potential tornado wind speeds across the United States. Section 423 of IBC 2018 now requires that structures housing critical emergency operations and certain Occupancy E buildings incorporate storm shelters in the darkest shaded area of the map. Source: Shelter Skelter, Structure Magazine

Thermal Efficiency

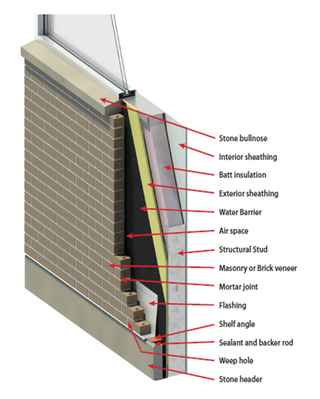

A way precast stands apart from masonry is with the continuous insulation that can be designed into the panels, helping achieve the thermal efficiency and R-value desired by engineers. The panels can be fabricated with continuous rigid insulation, leading to virtually zero heat loss. While it’s true that masonry with added insulation can achieve a similar effect, it also involves more trades to manage, not to mention the extra detailing for the design team.

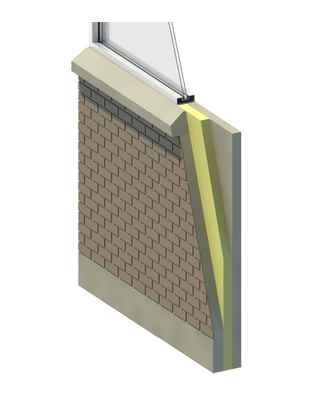

A graphic of a precast panel that has continuous insulation, providing better thermal efficiency.

A graphic showing a traditional cavity wall with a masonry exterior.

Prefab Benefits for the General Contractor (GC)

Speed of Construction

For the GC, the simplicity afforded by a prefabricated building is a no-brainer. With the building solutions produced offsite, often simultaneously with other phases of construction, it expedites construction. Additionally, prefabricated system installation is not weather-dependent, meaning there are fewer delays. Finally, to combat worker shortages or install in multiple shifts, if needed, GCs can lean on the precaster for installation and sealant services. Those are crucial advantages for the typical contractor in the education space, as they often operate under strict and unyielding deadlines.

Project Coordination Advantages

When a total precast solution is used that integrates structural and architectural systems, the GC also benefits from single source responsibility, with fewer trades to manage, translating into improved site safety and a cleaner and less congested site.

At the end of the day, the choice between prefabricated systems and masonry will likely depend upon a variety of project-specific requirements, budget constraints and stakeholder preferences. A comprehensive evaluation of these factors will help determine the most suitable construction method for your project. Finding a building solution partner that understands the K12 market type, schedule needs and budget constraints can go a long way in creating a seamless project experience. See how Wells is using prefabrication for K12.

Sourced Articles:

[1] https://zoom.us/j/3819530163?pwd=cHNEa1JvZk9SVS9RQUt5bzlSRW4wQT09