The owners of a dairy processing facility in southwestern Wisconsin waited far too late to address the deterioration of their dryer tower. The damage had become so severe that the USDA forced the dairy company to shut down operations until repairs were made.

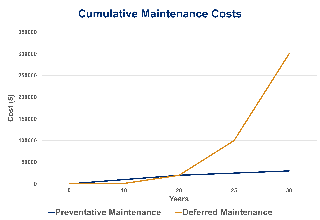

By neglecting preventive maintenance on the structure since its construction in the 1980s, the owners allowed the damage – caused primarily by water infiltration and hundreds of freeze-thaw cycles – to become excessive. What could have been a $13,000 routine maintenance caulking job ten years earlier had instead become a $300,000 concrete overhaul. The potential savings from regular maintenance are significant.

Even though precast can be one of the longest-lasting building materials on the market, this scenario is playing out at facilities across the country—a lack of preventive maintenance at regular intervals results in the costly deterioration of a structure. Once the issue presents itself, the damage rate is not linear but exponential – once the water breaks the sealant barrier, a $10,000 repair can quickly become $20,000 in two years, then $50,000 in three.

It's essential to be proactive with inspections and maintenance.

Water is an undeniably destructive force, particularly in northern climates. A small pinhole in the seal of a concrete panel can allow gallons of water into a joint, and once water infiltrates the structure, multiple freeze-thaw cycles often accelerate damage.

Even though they’re typically warranted for up to a decade, joint sealants can be susceptible to deterioration over time. Many owners don’t have an established schedule for routine sealant inspections. Their facility management and maintenance teams often focus on the facility’s working components, with little attention paid to the structure.

There are various reasons for this. Owners often postpone performing regular maintenance checks because they perceive them as unnecessary, don’t account for them in the budget, or are unaware that they need to be done. Nevertheless, regularly scheduled inspections cost almost nothing and could save significant sums in the long run.

Inspections aren’t complicated or time-consuming, and many prefabricators will offer to train a maintenance team on proper inspection techniques by using an inspection protocols checklist provided by the Precast/Prestressed Concrete Institute (PCI).

A simple one-to-two-hour annual walk-through is all that’s needed for most buildings. During this walk-through, a designated team member inspects the joints, looking for evidence of cracking or deterioration in the panels or sealants and ensuring that they’re in good working order. Most damage will be visible to the naked eye, so no special tools are necessary.

Parking structures should be inspected semi-annually, typically in the spring and fall, since a garage’s horizontal surfaces can trap water, dirt and grime. Annual washdowns are also recommended in the northern climates, where corrosive road salts and sand can wreak havoc on concrete and joint sealants.

Additional inspections might be necessary following significant weather events, such as hailstorms and natural disasters like tornados, hurricanes, earthquakes, or extreme sun exposure.

Of course, accounting for maintenance is an essential first step, and many sealants and restoration service providers can assist their clients with developing and maintaining a maintenance budget. Ultimately, by implementing a system of inspections at prescribed intervals and then re-caulking and re-sealing when necessary, most owners can preserve the integrity of their buildings for 50, even 100, years.