To understand what happens to a pre-stressed strand once it is cut in concrete, one must first understand its purpose.

The Purpose of Pre-Stressed Strands in Concrete

Concrete is very strong in compression and weak in tension. Compressive strength of concrete is the maximum compressive load (stress) it can carry per unit area. Tensile strength of concrete is usually considered about one-tenth of its compressive strength. So how can we take advantage of concrete’s compressive strength to improve tensile strength? The answer: add compression at locations of tension in order to obtain a tension that is below the cracking limit.

Professor Gustave Mangel's Theory of Pre-Stressing

Professor Gustave Mangel developed the concept of pre-stressing in the 1940s and brought the ideas to America in 1946. He explained the concept of pre-stressing using his famous stack of books theory (figure 1). The books at the bottom are like pre-compressed concrete. Utilizing this compressive force, they support their own weight, plus additional superimposed loads, simulated by the stack of books on top. So by adding a squish on the lateral stack of books, they stay in compression and can support the stack of books on top, without falling apart.

Selecting and Implementing Pre-Stressed Strands in Concrete

How can we accomplish this in a concrete piece? First, we specify the type of pre-stressing strand we want to use to add the squish. Typically, 7 wire ½” diameter 270 ksi Lo-Lax is used in precast structural members (figure 2).

The area of ½” diameter strand is only 0.153 square inches, between the area of a #3 and #4 bar. Because of its higher ultimate strength, this strand can be pulled to a maximum of 31,000 lbs, which is 2.5 times the maximum tensile strength of #4 bar.

Process of Applying Strands to Concrete Forms

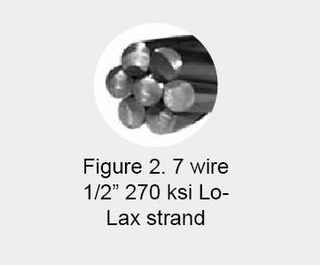

To get this force into the concrete member, first we must anchor the strand to a form, capable of handling the total prestress force without buckling (figure 3). Hydraulic jacks are used to pull each ½” 270 ksi Lo-Lax strand to 31,000 lbs. Strand elongation readings are taken, to ensure PCI tolerances, and then concrete is poured into the form, around the prestressed strands (figure 4). When a strand is stretched, the diameter of the strand decreases a little bit. Upon cutting it, the diameter will increase a tiny bit as it wants to shrink back to its original length, like a rubber band, slightly recessing into the concrete member at each end. This creates an added compression force, or squish, to the concrete member.

Determining When to Cut Pre-Stressed Strands in Concrete

When can we cut the strand to transfer its prestress force to the concrete in the form of a compression squish? ACI 318-14 specifies a maximum stress of 0.6f’ci’, however, PCI states that common industry practice allows us to increase this to 0.7f’ci’ .

This means that however much compression stress we are adding to the concrete member by all the tensioned strand, while considering self weight of the member, we must have a minimum of 1.43 times that compressive stress in the concrete when the strand is cut. Once cylinders have been broken to verify the concrete’s compressive strength meets this requirement, only then can we cut strand and strip the pre-stressed concrete member.

So now that we have cut the strand, what stops the strand from shrinking to its original length and how does the initial prestress force get transferred to the concrete member? By its bond to the concrete. The length required to bond the initial prestress force of the strand is called the transfer length. ACI 318-14 defines this transfer length as dbfse / 3 where db is the diameter of the strand in inches, and fse is the effective prestress, in ksi, after all losses (figure 5). If we have one strand pulled to 31,000 lbs, the transfer length is the length required to put the 31,000 lbs, minus some losses, into the concrete member. So, fse is the effective stress put into the concrete, by the strand, that decides whether the concrete member will be uncracked, in transition to cracking, or a cracked member, under a specified loading condition, after all losses are taken into account.

Understanding Losses in Pre-Stressed Strands

What exactly are these losses that keep getting mentioned? Loss of prestress force is the reduction of prestress force in strand due to elastic shortening, shrinkage, creep, and other external factors. So if we pull 31,000 lbs on a strand, we don’t necessarily get 31,000 lbs into the concrete at final service loading conditions.

- In elastic shortening, the concrete around the strands shortens as the prestress force is applied to it.

- During plastic shrinkange, the hydration of cement results in a reduction in the volume of the concrete.

- Drying shrinkage appears after the setting and hardening of the concrete mixture due to loss of capillary water.

- Creep is the time dependant deformation of hardened concrete due to a permanant force.

In all these losses, strand goes along for the ride and shrinks as well. Creep in the strand, also known as relaxation, is a reduction of force, in the strand, under constant strain. Once the strand is pulled, then released, the extra length required for the strand chuck to properly seat and hold the strand is a type of external loss. All these losses add up, to reduce the initial pull, or initial stress, to the actual pull, or effective stress, fse.

Determining the Ultimate Strength and Development Length in Pre-Stressed Strands

But what if we want to know when the strand will break? This limit is called ultimate strength or nominal strength. How much more bond length is required? The total length required to develop a strand’s ultimate strength is called the development length. ACI 318-14 defines the development length as (fps – fse)db plus the transfer length, where fps is the stress in the strand when a concrete member fails in bending. The transfer length is always a portion of the development length (figure 5). In figure 6, the transfer length can be seen going from zero to the dotted fse = 170 ksi effective stress line, and the full development length goes all the way up to the dotted fpu = 270 ksi line, where fpu is the specified ultimate strength of the strand. For our ½” strand pulled to 31,000 lbs, and assuming 15% losses, we get an effective stress of around 170 ksi. The transfer length to apply 170 ksi to the concrete is approximately 27” and the development length to break the strand at 270 ksi is approximately 78”. Notice in figure 6, that a partially debonded strand’s transfer and development length are doubled. This occurs when strand is intentionally debonded with sheathing, goes through an opening where strand is removed, like a window, or when openings are cut through strand and into the member at a later date.

Understanding Pre-Stressed Concrete Behavior Under Loading Conditions

We have learned that the effective prestress, fse, is what keeps a pre-stressed concrete member in an uncracked state under service loads and fps is the stress in the strand at the members ultimate bending strength, when failure occurs. So, what happens in-between? Usually, pre-stressed concrete members will remain uncracked under service loads, and have have some wiggle room to take more loading prior to strand breakage, to ensure a ductile failure. That way, we can detect impending failure by serious deformation and serious cracking, long before failure will occur.

Some minor cracking can be normal under service loading as well, depending on the size of the member, span of the member, number of strand, the loading criteria, etc. What holds the pre-stressed concrete member together after cracking is the leftover tensile strength of the strand, and compression at the top of the member, (in typical positive moment bending). Figure 7 shows a beam designed by students from Minnesota State University, Mankato, for the PCI big beam contest. The contest specifies a loading condition to remain uncracked, and a higher loading condition to break. This beam has been loaded well above its cracking limit and below its ultimate bending strength. The beam still takes on loading, due to the tension in the strand crossing the cracks at the bottom of the member and the compression at the top of the member, informing us of an impending failure.

The Role of Strand Cutting in Pre-Stressed Concrete Construction

Now we know that by cutting strand, a squish is added to a concrete member, similar to Gustave Mangel’s stack of books. The strand must be tensioned in a concrete form, cut at a minimum concrete strength, enough effective stress applied to keep the member uncracked with all losses taken into account given enough transfer length; and a ductile failure will show serious cracking prior to member failure at ultimate bending stress given enough development length. Cutting strand is what turns the squished books into multi-level total precast pre-stressed concrete buildings.