Structural Column and Beam Building Solutions

Prefabricated columns and beams optimize construction projects by working together as a structural system, streamlining assembly, enhancing stability, and improving overall project efficiency.

What is a precast concrete column?

Precast columns are vertical structural elements used to carry larger framing elements with heavier loading. Typically rectangular in shape, they can support beams or spandrels of the structure down to the foundation. Sizes vary greatly depending on structural demand; it is important to determine the framing spans early in the project development to help locate and layout required column locations.

The primary benefit of designing with precast columns is the superior structural load-bearing capacity.

The Interrelationship of Columns with Other Structural Elements in Design

Columns are generally needed at the perimeter of a structure to support any spandrels or beams. Support haunches can be provided on any face of the column to allow for variation of the building framing. These can be used to support precast as well as other building materials. Columns typically span multiple levels to increase erection flexibility.

What is a precast concrete beam?

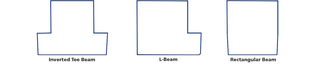

Beams are structural components used to transfer floor loads to support walls or columns. Generally, beams are produced with three general shapes: an inverted tee beam, an L beam, or a rectangular beam.

Structural Flexibility of Beams

Inverted tee beams and L beams are designed with ledges to support slabs and optimize structural detailing, potentially reducing the amount of steel required. If greater floor-to-ceiling clearances are desired, these ledges can be utilized instead of rectangular beams with steel bearings on top, thus increasing headroom heights. For more detailed information on these beam shapes and their applications, refer to our Design Guide Series Episode 2.

Designing with precast beams offers significant advantages, including the ability to achieve long spans and shallow sections, which allow for greater clearances.

Achieving Fire Resistance and Durability with Precast Columns and Beams

Columns and beams possess inherent fire resistance and durability due to their typical shape and size. When haunches are used to support other precast members, adjustments can be made to the concrete cover on the haunches to meet specific fire resistance requirements corresponding to the building type.

Manufacturing Columns and Beams in a Quality-Controlled Environment

Precast columns and beams are manufactured in a quality-controlled environment, ensuring consistent quality. Columns are poured horizontally with three sides enclosed to maintain a uniform finish, with the option to vary the screed finish based on project specifications, usually matching the other faces. They are typically prestressed to reduce cracking and enhance manufacturing efficiency, facilitating easier handling.

Similarly, beams are cast horizontally with three sides poured against a steel form to ensure a smooth finish. The exposed top of the beam can feature various finishes as required for composite action in design or a smooth surface for insulation or aesthetic purposes. Alternatively, beams can be cast on their sides to achieve architectural finishes resembling walls and spandrels, offering versatility in design applications.